-

GMS Quality Assurance and Standards

As specialty contractors, quality assurance is built into every stage of production. With monotoned precision across the entire manufacturing process from pattern design to finish.

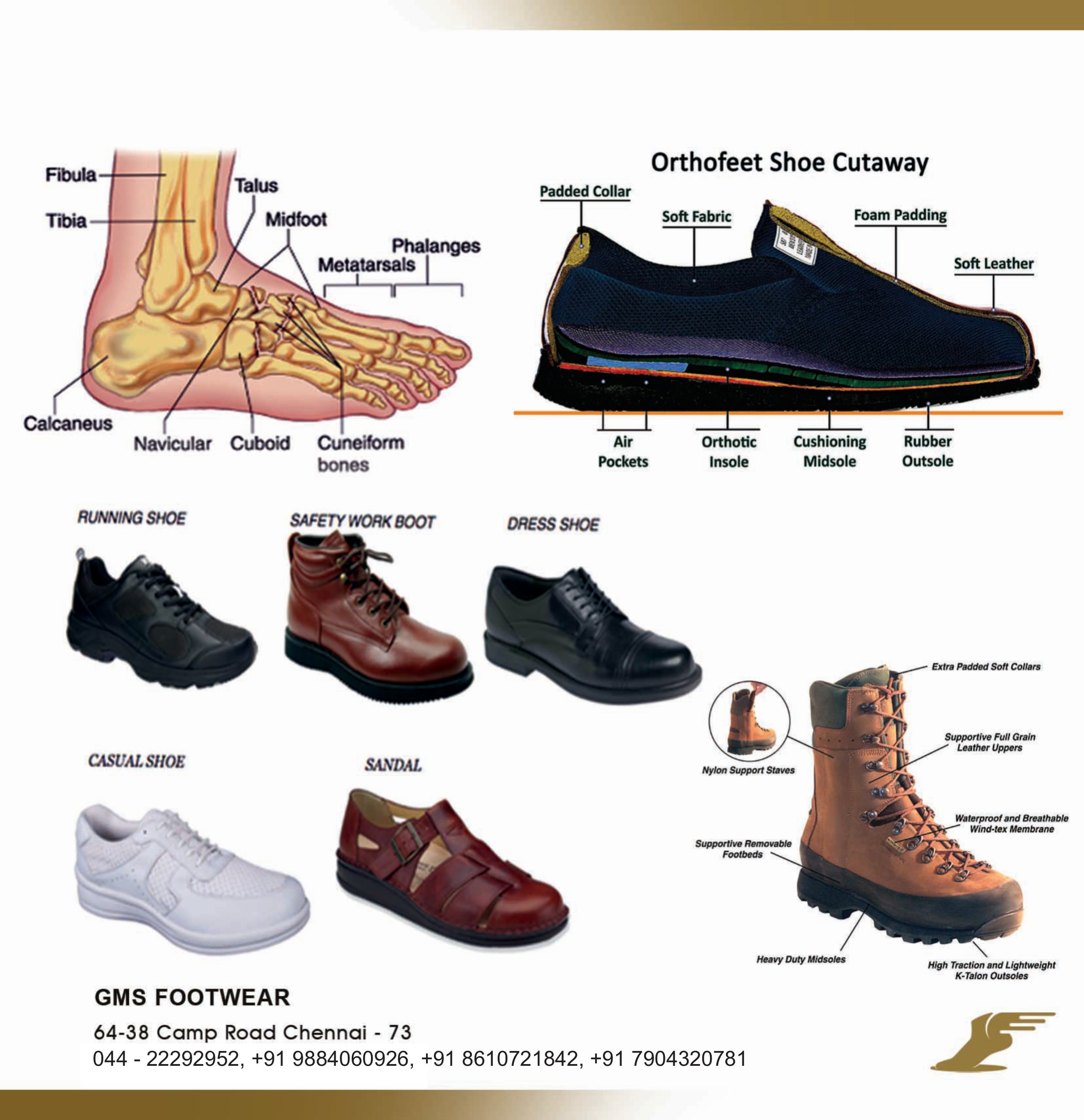

No orthopedic requirement is too complicated or individualized. Our in-house technical staff go to great lengths to design orthopedic shoe and sandal solutions with accurate functional support combinations. Constitutive materials are MCR, silicon and allied composites.

Micro Cellular Rubber, sourced from a single South Asian nation is a proven cure for several foot disorders including leprosy. This controlled medicated material is supplied through the government agency to select R & D laboratories and medical centers. Recent research incorporates Intelligent composites as certified for ortho-care.

Certified Designer Shoes and Sandals

- Congenital deformity. Structural deviance present at birth. For instance, an individual born with a deformed or missing limb.

- Traumatic injury to one or both lower limbs, caused by industrial or vehicle accidents, for instance.

- Disease progressively affecting one or both feet, as occasioned by bone irregularity caused by arthritis, osteomyelitis, or diabetic amputation.